<strong>The HTMU warehouse in Utrecht is a robust industrial building that reflects the timelines and history of the new Wisselspoor neighborhood. The warehouse is therefore designated as a hotspot for the neighborhood and the Spoorpark. Commissioned by Primestone Development, Ruland Architecten added short-stay apartments to the HTMU warehouse. By placing these apartments on top of the existing building, the warehouse remains a large, recognizable space and open to a new program for the neighborhood. At the same time, this creates a feasible and realistic plan for restoring this distinctive building.</strong>

On the edge of Utrecht’s city center, the ambitious Wisselspoor plan has been developed on a former railway-related industrial estate. The area boasts a wide variety of railway-related heritage, giving it a strong identity within the city. One of the remaining robust buildings within Wisselspoor is the HTMU warehouse. This former Traction and Rolling Stock Utrecht Recovery Center plays a defining and stimulating role in the Wisselspoor plan and is considered a hotspot for the neighborhood.

Primestone Development commissioned a study to determine whether it would be feasible to create 100 short-stay apartments in the HTMU warehouse while preserving its historic character and complying with urban planning regulations. The apartments will facilitate the growing demand for temporary accommodation in Utrecht without increasing pressure on the housing market, as established by the Utrecht City Council in its policy for short stay and hotels.

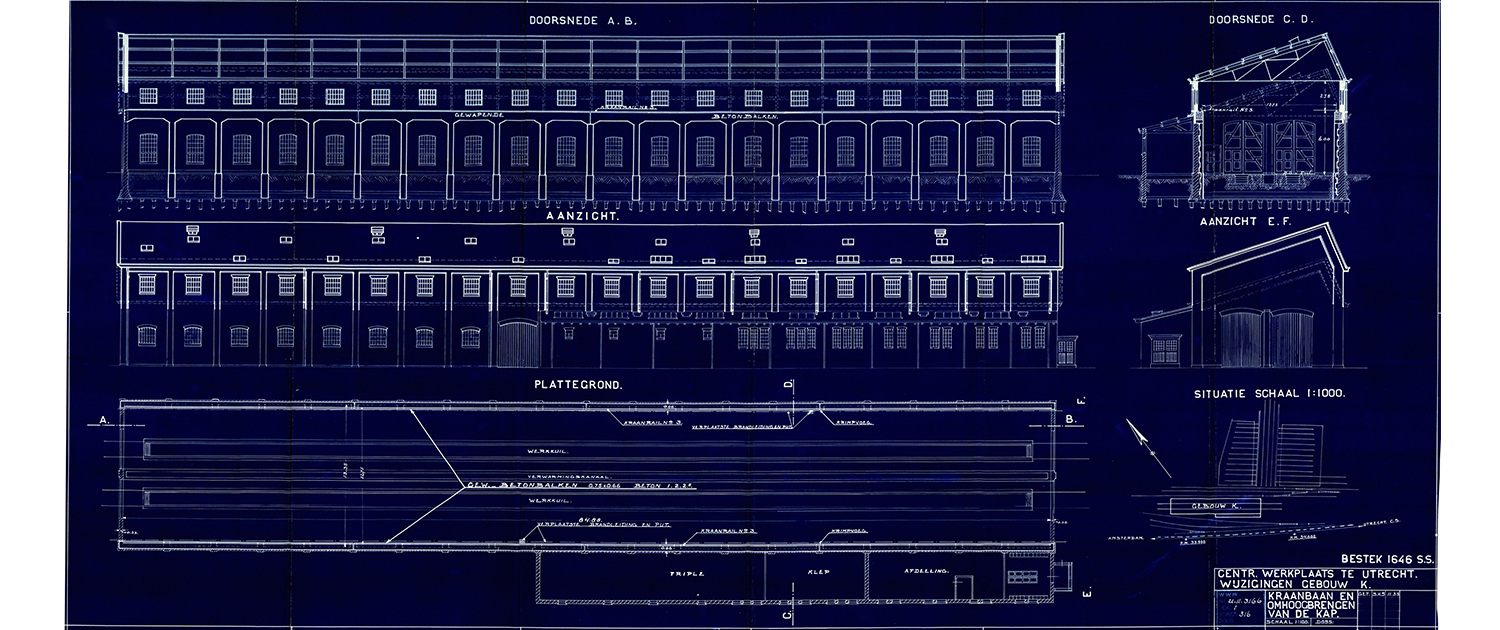

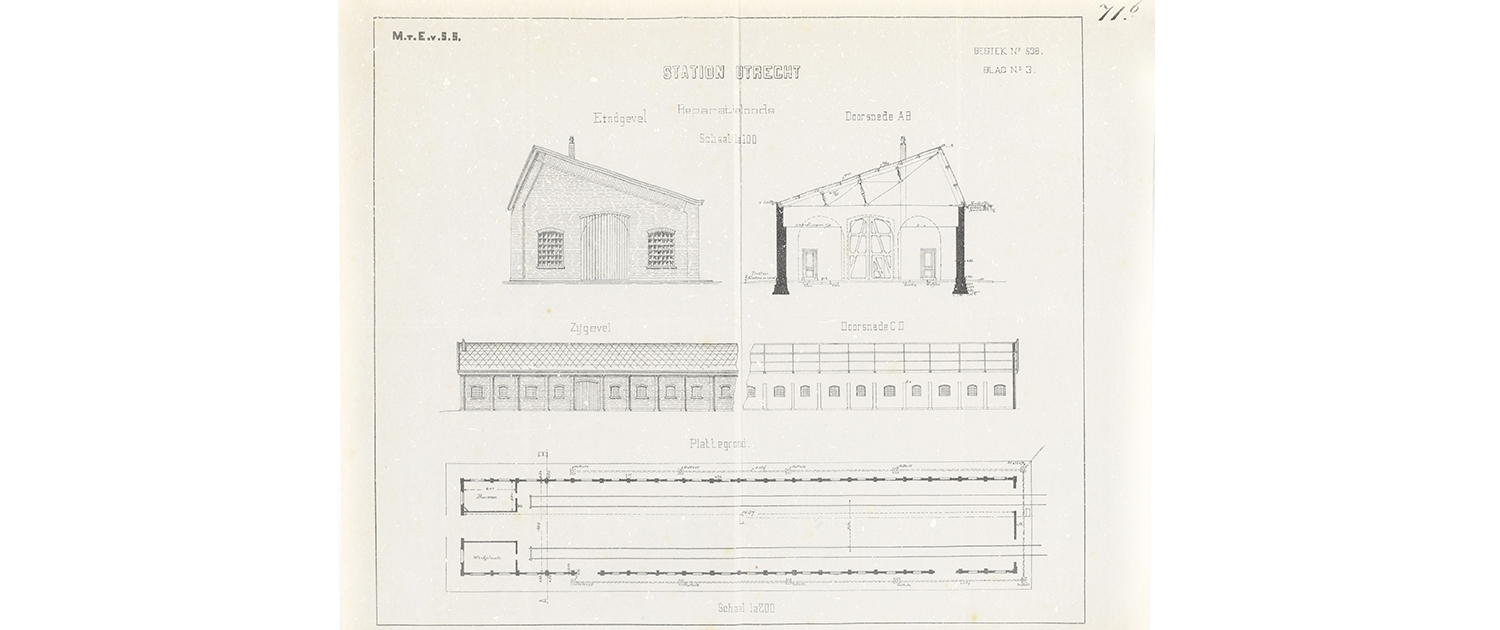

The HTMU shed was built in 1891 as a repair shed by the State Railways Company. In this shed, repairs were carried out on wagons, which were brought into the shed via the two tracks. Due to increasingly heavy maintenance work, the shed was raised in 1934 to accommodate a crane track. Inside, a completely new concrete structure was added to the facade, with rails that allow a crane to move through the warehouse

The facade was raised above the crane track, and the roof was reused. In 1939, the shed was extended on the west side, and a completely new shed was built against the long north facade for the overhaul of diesel trains. The outline of this shed is still visible through the white paintwork on the facade. On the railway side, an extension was added in 1939, consisting of a concrete frame with glass and brickwork infills, which is still present.

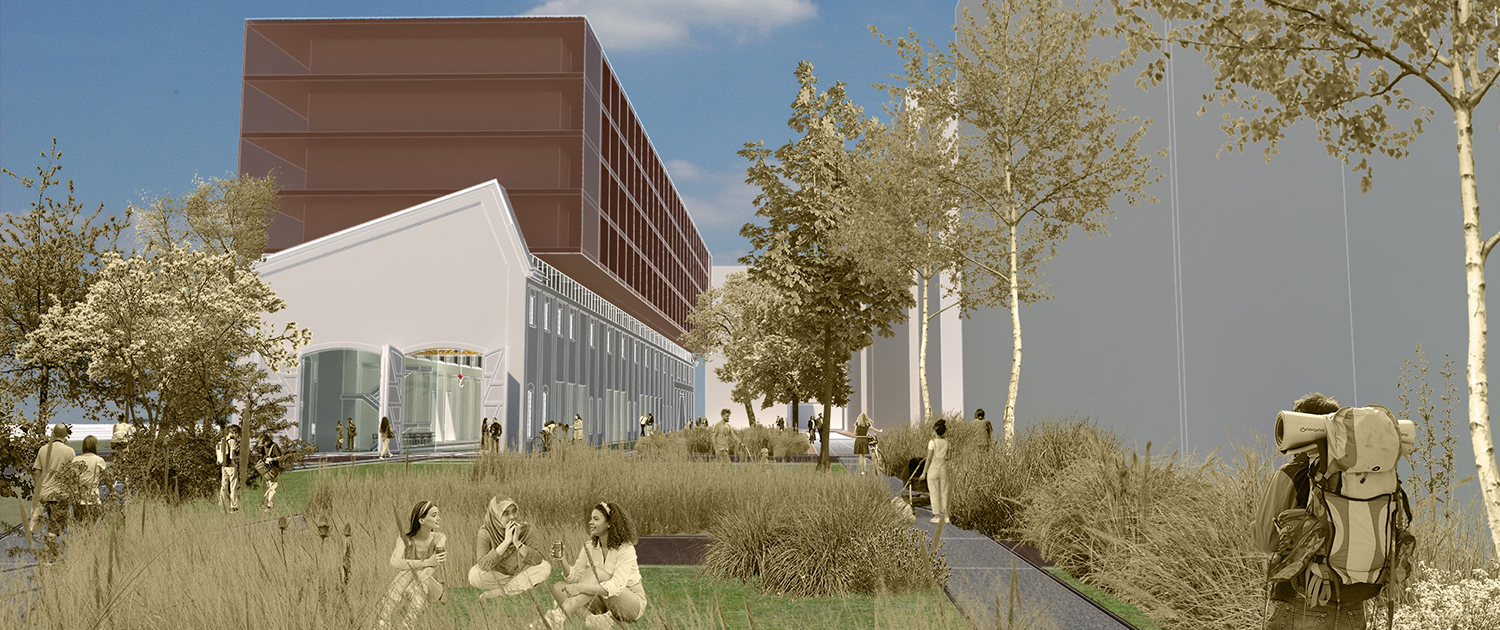

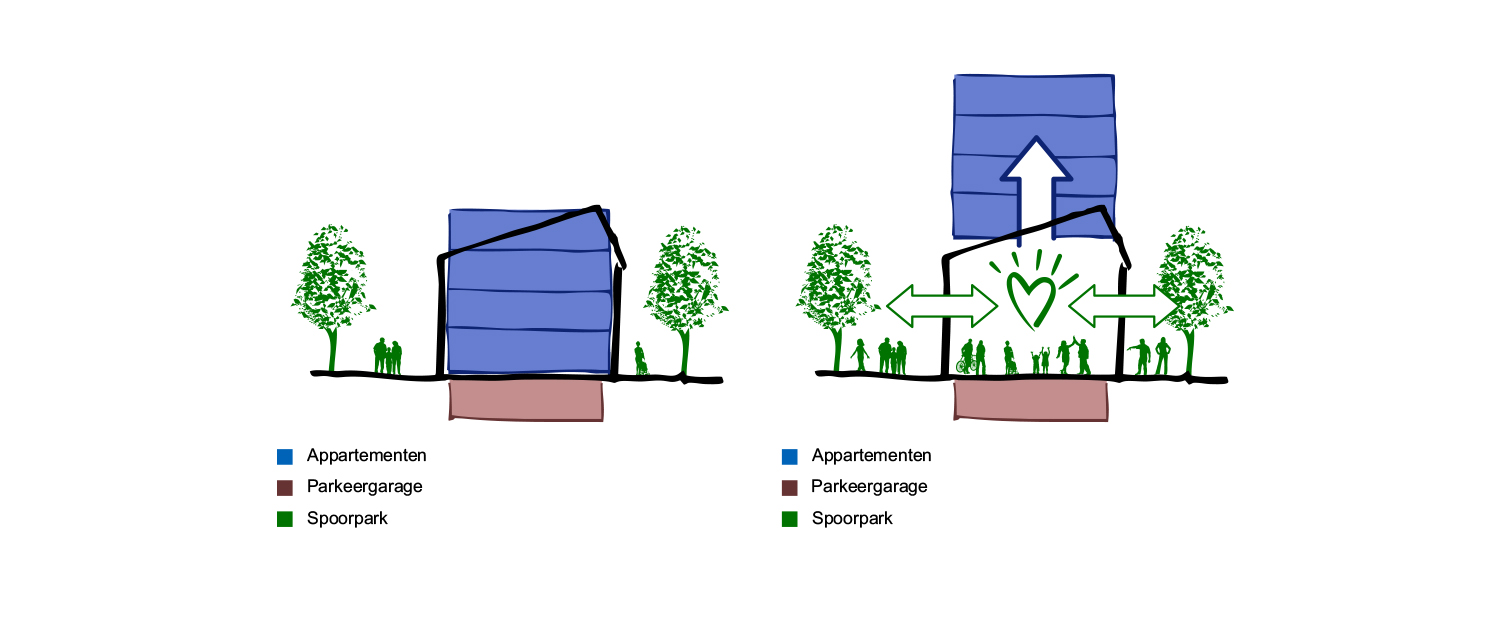

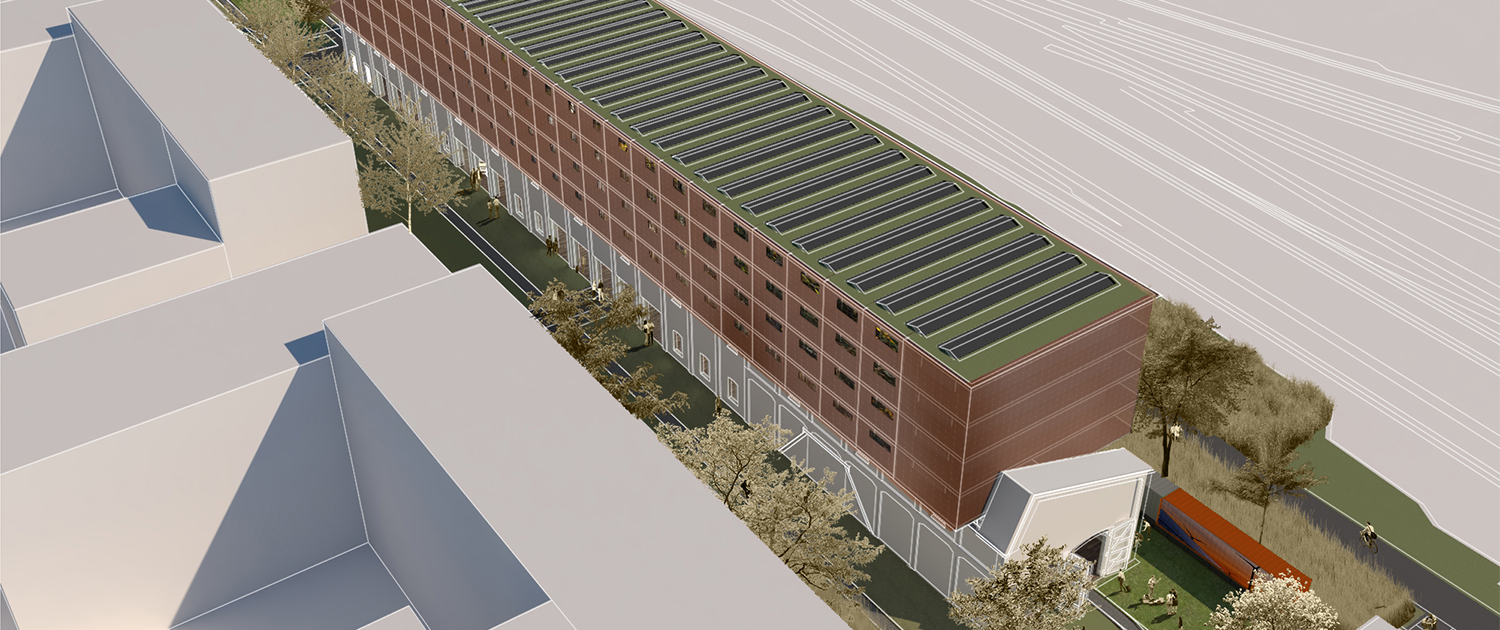

The starting point for the redevelopment of the HTMU warehouse is that a new, suitable use will preserve its recognizable industrial characteristics as much as possible. Enclosing the warehouse would have lost its characteristic length and the rhythm of the large train workshop. By placing the apartments on top of the existing building, the 115-meter-long warehouse remains a large, recognizable space and opens up for a new program as a hotspot or a boost to the neighborhood’s quality of life. Simultaneously, this creates a feasible and realistic plan for restoring this distinctive building.

The volume atop the warehouse is constructed of lightweight timber and contains 100 short-stay apartments of approximately 45m². The gallery access is located on the railway side of the structure, which, via elevators and stairwells, connects to the ground floor at the gables of the original warehouse. The glass-fronted gallery not only offers fantastic views of the railway landscape but also serves as a sound buffer. A carefully chosen structure has created a high-contrast volume that blends seamlessly with the streetscape and preserves the robust basement, the HTMU warehouse.

The new functions in the HTMU warehouse have different energy and water demands than the original train repair warehouse. A combination of solar panels on the roof and facade provides the necessary energy, which is stored in two batteries: one for electrical energy and one for thermal energy. Thanks to innovative technologies, the total energy demand from the grid is limited to just 12%, eliminating the need to expand the existing grid connection for the redevelopment of the HTMU warehouse.

In addition, a combination of rainwater and graywater treatment, coupled with an integrated management system, reduces water consumption for the new functions in the HTMU warehouse by more than 75%. The energy concept was developed by Circl Technologies and is explained in more detail via this link

.

| Location | Utrecht |

| Floor area | 11.400 m2 gfa |

| Year | 2024 |

| Status | Draft design |

| Client | Primestone Development |

| Architect | Ruland Architecten, Amsterdam |

| Owner of building | NS |

| In collaboration with | Circl Technologies |

| Images | Ruland Architecten, The Utrecht Archives, Circl Technologies |

Ruland Architecten

Koningin Wilhelminaplein 13

ruimte 1.11.07

1062 HH Amsterdam

Postbus 80018

1005 BA Amsterdam

+31 (0)20 423 66 89

info@ruland.nl